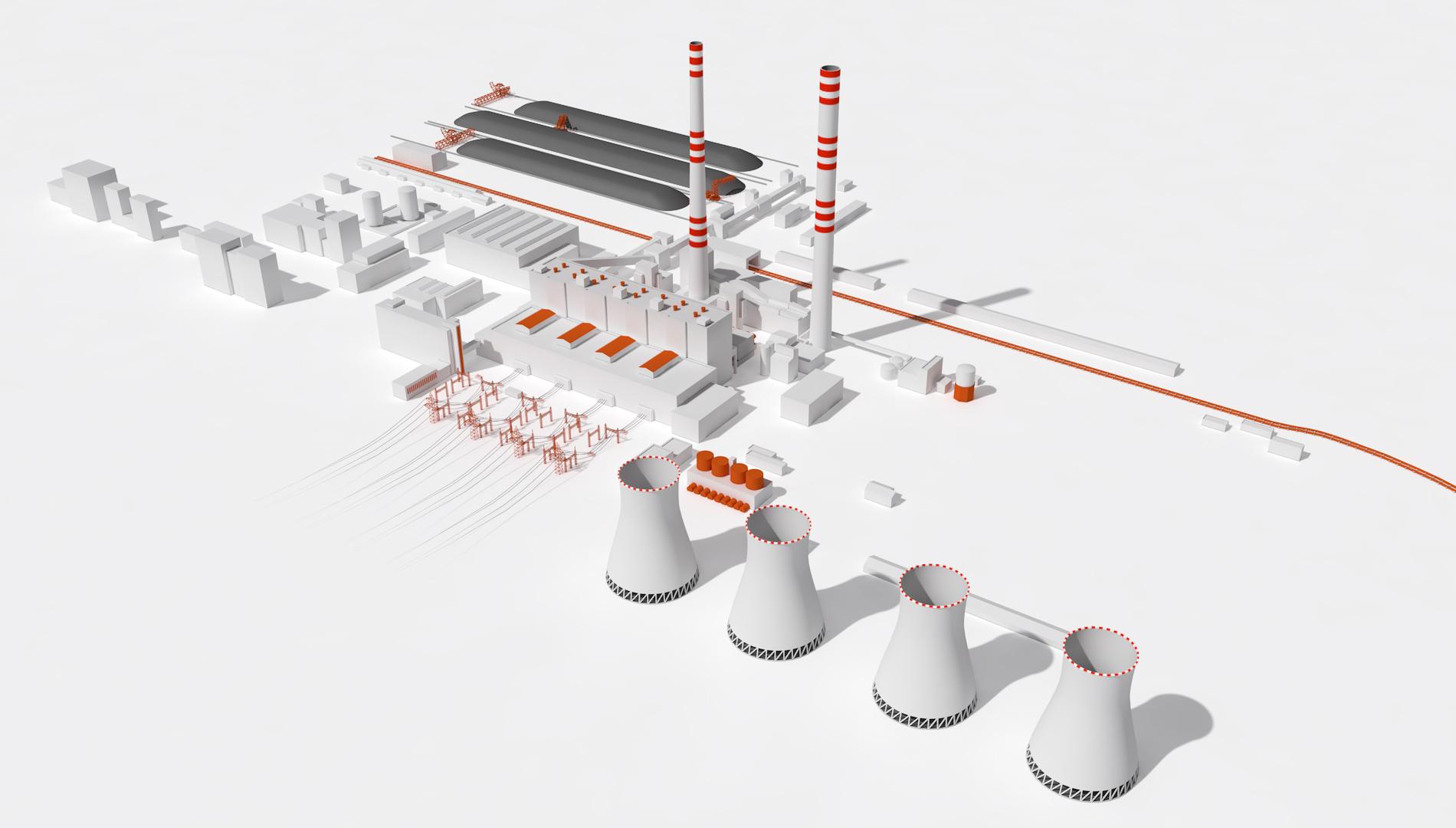

Aerial View of the Dětmarovice Coal Power Plant

At the Borders of Moravia and Silesia

Having Polish borders in our range of sight while in the middle of a dense agglomeration. That is Dětmarovice – the only pit coal power plant of ČEZ in the Czech Republic, which is a reliable distributor of heat for Bohumín and Orlová. Moreover, the region has its safe power supply ensured for the future too thanks to the last generous modernization, which cost CZK 400 million.

Dětmarovice (Dziećmorowice in Polish, Dittmarsdorf in German) itself is located in the historical language Babylon at the borders of Moravia and Silesia. Since long ago, many European cultures have been encountering one another, resulting in national rivalries and, unfortunately, several changes of state borders in the 20th century. After the abolishment of Austria-Hungary, the municipality would first become a part of Czechoslovakia, followed by Poland after the Munich annexation and the German Third Reich a year later, only to return under Czechoslovakia after 1945. The modern development of the municipality had been dictated by the coal tycoon family, the House of Larisch, who were the owners of Dětmarovice from 1792 all the way till the end of the Second World War.

The state border has remained close to Dětmarovice to this day. The rivers Petrůvka (Piotrówka) and Olše (Olza) are literally only a few tens of metres away from the fences of the power plant's site. Thanks to the panoramic aerial shooting, the flat landscape offers interesting views in basically every cardinal direction. The most interesting views can be found to the South-East and East, with the ridge of Moravian-Silesian Beskids towering over the horizon – from Velká Čantoryje (995 m.a.s.l.) at Třinec, to the highest peak of the Lysá hora chain (1323 m.a.s.l.) to the cult mountain Radhošť (1129 m.a.s.l.).

However, the municipality is located much closer to the individual urban units of the North-Moravian agglomeration, as well as one large pit coal field, which is the reason for the rapid industrialization that happened here over the last 200 years. Ostrava is located West of here, Karviná is to the South-East and looking Westwards gives us a great view of Bohumín. South-West of Ostrava, towards Olomouc, we can see the ridge of the Oderské vrchy. Westwards towards the direction of Opava, there is Hlušínsko, behind which we can more or less visualize – rather than actually see – the massif of Hrubý Jeseník with its Dominant Mountain Praděd (1492 m.a.s.l.). To the North, just over the border, there are the large Polish cities of Wodzislaw Slaski, Biertultowy and Rybnik; to the North-East, we can see the spa of Jastrzebie-Zdrój.

Dětmarovice Pit Coal Power Plant

The Dětmarovice power plant is located in the northern, industrial part of Dětmarovice, right next to the main railroad leading from Bohumín to Žilina. With its total power output of 800 MW, provided by 4 production blocks of 200 MW each, it is the largest traditional power plant in the region of Moravia-Silesia and all of Moravia, as well as the largest contemporary Czech power plant to use pit coal as a fuel. Its construction began in 1971, with blocks having been phased into the network from May 1975 to November 1976. Energoprojekt Praha was the supervisor of the project, with VOKD Ostrava providing the construction parts and Škoda Plzeň providing the technology. Originally, the power plant belonged to the Association of Power Plants of Ostrava-Karviná, but moved on to become a standalone organizational unit in 1990. The ecologization of the plant was finished in 1998, mostly involving complex desulphurization. All flue gases produced by the Dětmarovice power plant pass through several emission reduction devices; these lower the contents of nitrogen oxides and flue dust.

A hot innovation came to Dětmarovice in the summer 2015 in the form of a modernized flue gas denitrification device, which is unique within the Czech Republic. Thanks to this, the amount of nitrogen in the exhalation is reduced by approximately 50 percent and allows the power plant to be viable even after 2020. The flue gas modifications have reduced the volume of generated nitrogen oxides, with the remaining nitrogen oxides being removed thanks to the catalytic converter. This investment, which will also ensure compliance with the strictest limits, has also seen a contribution from the European Union – the EU Solidarity Fund as a part of the Environment programme – as high as CZK 155.4 million.

The power plant produces 2.5 TWh of power every year (more than 700,000 households worth of power consumption), as well as over 700 TJ of heat, which is delivered to about 50,000 inhabitants of Orlová and Bohumín. The construction of hot water lines started in May 2009 and the first delivery was made in autumn 2010. The joint production of heat and power in one cycle, called co-generation, reduces the fuel consumption per unit of energy, thus making it more environmentally friendly.

During very low temperatures in winter, up to 650 m3 of hot water (140°C) pass through the heat plant's heaters every hour. The total yearly heat supply is about 400 TJ for Orlová and about 200 TJ for Bohumín. The remaining over 100 TJ supplies the power plant itself and consumers from its surroundings.

Watch the animation describing how a coal power plant works!

The technological equipment of the power plant is cooled via enclosed cooling circuit, supplied with water from the Olše river. Apart from power, EDĚ also provides heat in the form of hot water for Orlová and Bohumín. The effectiveness and functionality of all of the power plant's equipment is independently and continually monitored. It is also a subject of regular inspections of administrative and environmental authorities, namely the Czech Environmental Inspection and the Regional Bureau of Moravia-Silesia. The power plant has attained the certificate "Environmental Management System" and currently complies with ISO 14001.

The combustion processes during power and heat generation have their by-products, also called Power Side-Products (PSP); these are a raw material for other productions and processes. The power plant of Dětmarovice produces about 400,000 tonnes of PSP a year. 90% of this amount consists of ash matter, further certified and used for construction industry – mostly as an ingredient for cement, concrete or porous concrete. The remaining 10% comes in the form of flue gypsum, which is a by-product of desulphurization used for re-cultivation purposes along with a portion of the ash matter.

Aside from fulfilling their main mission – power production – the power plant of Dětmarovice is also the natural cultural and social centre of the municipality. There are not only regular Open Doors Days, but also various trade fairs, meetings and other accompanying events.

Control room

The two control rooms are the brains and the controlling centre of the whole power plant. This is the actual source of commands for the individual parts of the production. All four power blocks, as well as the majority of joint devices, are controlled from the control rooms.

At full operation,up to seven specialized personnel work here.

Overall View of the Generator Room

The generator room is fitted with four turbo-generators (turbine + generator). Each turbine has nominal power of 200 MW, nominal rotation speed of 3000 n/min and consists of three parts (high, middle and low-pressure). The turbine ensures the conversion of steam's thermal energy into mechanical energy. The main generator is on the same shaft with the turbo-generator, converting the mechanical energy into electrical energy – producing power at a voltage of 15.75 kV.

Generator Room between TG1 and TG2

The overheated steam enters the high-pressure part of the turbine at a pressure of 16.18 MPa and a temperature of 535 °C. Past the high pressure part, the steam returns into the boiler, where it is re-heated back to 535°C and proceeds to the middle-pressure part, followed by the low-pressure part of the turbine. After passing through the low-pressure part at the temperature of 30°C, the steam condenses into water. For this physical effect to happen, it is necessary to maintain a very good vacuum inside the condenser. The water coming from the condenser is gradually heated and pumped into the feeding tank, from which it is returned to the boiler under very high pressure (up to 23 MPa) using a turbo-feeder or two backup electro-feeders.

Generator Room between TG3 and TG4 – 0 m Elevation

The blocks 3 and 4 feature a newly installed technology called DENOx. The only device of its type in the Czech Republic, it utilizes the selective-technology catalytic reduction to reduce nitrogen oxide emissions. The NOx separation itself is performed via catalytic converter. A small amount of ammonia water is injected into the flue gas right before the converters as a "startup reagent". The same technology is used for diesel engines in trailer trucks – the trade name of the "startup reagent" is AdBlue.

Generator Room between TG3 and TG4 – 10.8 m Elevation

The Dětmarovice power plant is obliged to comply with the following emission limits:

- for cinders (100 mg),

- sulphur oxides (500 mg),

- nitrogen oxides (650 mg),

- carbon oxides (250 mg).

However, thanks to the aforementioned technology of DENOx, the power plant now fully complies with all legal measures valid from 1 January 2016. These limits set the emission limits to 20 mg of cinders and 200 mg of sulphur and nitrogen oxides, among others. The limits are subject to the BAT and PREF parameters (the requirement to comply with the best accessible equipment), coordinated by the European Union.

Boiler Room – Mills

The average daily fuel consumption of one block in the power plant of Dětmarovice is approximately 1600 tonnes (about 32 railway cars) of coal. After being ground into very small fractions, the coal is burned in a total of four boilers with output of 650 tonnes of steam per hour. The boilers are made by the Vítkovice Machinery Group, with forced circulation two-pass system and granulating combustion chamber. Their efficiency is around 90%; the highest boiler temperature is 1400°C. Each boiler is provided with a milling device, consisting of four milling circuits with 33t/h ring mills. The full performance of the boiler is ensured by three mills, with the fourth one providing a backup. To put things into perspective – the milling granularity is identical to that of semi-coarse flour. The boilers are started up using natural gas, with an electrical spark used to ignite the gas burners. On a separate frame in the rear part of the boiler, Ljungstrom regeneration burners are installed to ensure the heating of the combustion air.

Boiler Room 25 m

Each boiler features two air and two smoke ventilators. The cinder is separated in four branches of electro-static separators of the system.

At 54 m in height, the boiler is hung by steel suspension points in the boiler building, which stands 62 m tall. It "extends" by about 15 cm during operation due to thermal dilation. The power of the boiler is 650 tonnes of steam per hour. The steam temperature is 540°C and the pressure is 17 MPa. Starting up from its cold state, a production block is capable of phasing in (in order to provide power into the network) within 5.5 hours, or even quicker in an optimal situation.

In the 25 m boiler room, we can also find a part of the technology used to reduce nitrogen emissions – the so-called primary measures. Via appropriate temperature and air distribution within the boiler's combustion chamber, these measures prevent the generation of an undesired amount of nitrogen, which in turn doesn't need to be dealt with.

From the Roof of the Separators

The electro-separators contain sparkling and latching electrodes for very high voltage (up to 70 kV). The chambers of the electro-separators have three sections. The first section captures the largest portion of the cinder while the last section captures the remaining share of the dust particles. On the electrodes, the passing cinder is electrically charged and proceeds to latch itself with the electro-static-force onto the oppositely charged desk electrodes. The rotary hammers of the shruggers periodically shrug the latching desk electrodes; the cinder falls into pressure vessels, from where it is transported into cinder silos via pneumatic transport.

The flue gases move from the electro-separators into the desulphurization unit for further cleaning. The flue gas composition is constantly monitored, measuring the content of sulphur, ash, carbon oxides and nitrogen oxides.

The efficiency of the device can be demonstrated very well statistically. Approximately 1 million tonnes of coal is burned in Dětmarovice during one year, producing about 200,000 tonnes of cinder. However, only 70 to 90 tonnes pass into the chimney, which is the equivalent of 0.04% or 3–4 cistern trucks.

Electro-separators from the Roof of the Boiler Room

The roof of the boiler room houses the exhaust pipes of safety valves from boilers, both high-pressure and low-pressure. On the horizon, we can see four cooling towers, standing 100 m tall. Behind us, we have two chimneys used for desulphurized and non-desulphurized flue gas. Each of them is 269 m tall and they comprise the predominant feature of the power plant.

The non-desulphurized flue gas is generated due to the limitation to the desulphurization technology. The currently employed technologies do not allow desulphurizing of flue gas during start-up or shut-down of the blocks. The chimney for the non-desulphurized flue gas is therefore only used for several tens of hours a year. The other chimney releases cleaned flue gas. The desulphurization device was provided by Mitsubishi. It consists of two absorbers (one for every two production blocks). It has been operational since March 1998.

From the roof, we can also see the chemical water treatment plant and the so-called demi-station used to produce de-mineralized water. This water is often very clean and high-quality, rid of all ion-dissolving substances and silicone in the form of SiO2. The demi water is electrically non-conductive. It is used to produce steam.

Fuel Storage from the Roof of the Boiler Room

The coal deliveries are made exclusively via railroad. The main suppliers are OKD and Polish partners. The pit coal is the only fuel for the power plant. Compared to standard coal, it has twice the heating potential, i.e. less than half the amount is needed to produce the same amount of thermal power. From the general point of view, the pit coal supply in the region of Ostrava-Karviná and the nearest Polish region is enough for the upcoming 100–150 years. The pit coal is also more profitable fuel regarding the amount transported, lower emissions produced by boilers, and lower amount of power side-products (ash matter, gypsum). Compared to standard coal, the thermal energy is substantially more concentrated in pit coal.

Pit coal is received at varied quality levels, which is why fuel homogenization has to be carried out after each delivery when storing the fuel – so-called buffer stocking. Each fuel has to pass the buffer stock. The homogenization process involves storing the fuel in the stock lengthwise, followed by withdrawing it diagonally. This ensures its unchanging quality before delivering it to the boiler room. In the boiler room, the fuel is subsequently milled up inside the milling lines and blown into the boiler.

The capacity of one buffer stock is 100,000 tonnes of fuel. The total buffer stocking capacity is therefore 300,000 tonnes of fuel. The fuel consumption depends on the number of blocks in operation. Since every block is capable of regulating its output within the range of 100–200 MW, its fuel consumption can be 1,000–2,000 tonnes a day. The stocks are refilled continually, with the current season and fuel purchasing economics taken into consideration.

The main coaler belts provide fuel supply for all the boilers of the power plant in Dětmarovice.

The fuel-thawing tunnel is used to ensure that it is still possible to unload the fuel to the buffer stocks even during winter operation.

De-carbonization station

The de-carbonization station is used to treat cooling water. The water is pumped from the Olše River, located approximately 6 km from the power plant. From its raw state, the water is processed into cooling water (according to required parameters) and demi water used to feed the boilers. The flow through the cooling tower can reach up to 6,000 litres per second; the cooling ranks are 2 m in diameter.

Power Outlet from the Roof of the Boiler Room

For purposes of transport, the produced power is transformed to the voltage of 110 kV and led out to four lines. The flexible setting allows switching individual blocks between individual lines. The power of the blocks is subsequently distributed into surrounding distribution facilities of very high voltage.

Power evacuation

For purposes of transport, the produced power is transformed to the voltage of 110 kV and led out to four lines. The flexible setting allows switching individual blocks between individual lines. The power of the blocks is subsequently distributed into surrounding distribution facilities of very high voltage.

Cooling Towers

There are four cooling towers prepared for the four power blocks. In theory, however, considering the operation economy, it is possible to interconnect the cooling circuits in various ways, i.e. all four cooling towers can be used to cool one block, as well as all four blocks only being cooled by two towers. The block operation economy changes based on the amount of operated towers. It is necessary that the efficiency of the blocks is as high as possible, which is why the cooling circuits are regulated.

The cooling circuit also includes condensers, which consist of a total of 15.5 km of brass piping. These are cooled using water from the enclosed tower circuit at a flow-through of about 6000 l/s.

Help

Left-click and drag to choose the viewing angle, or use the keyboard.

| Go to the main homepage | |

| Go to the power plant’s homepage | |

| Show information about the viewed part of the excursion | |

| Show your position in the power plant | |

| Show the thumbnail gallery | |

| Zoom in | |

| Zoom out | |

| Pan to the left | |

| Pan to the up | |

| Pan to the down | |

| Pan to the right | |

| Help | |

| Enter full screen mode |